A New Stormwater Detention System For Boulevard Hymus

Pointe-Claire, QC Product: Cultec® Stormwater ChambersCULTEC® Recharger and Contactor chambers are used for infiltration, detention and/or retention of stormwater underground. The system is comprised of thermoplastic arch-shaped chambers surrounded by clear crushed stone. Water enters the system through a separator row and then flows through the stone and into a chamber row prior to exiting. The CULTEC stormwater system is sized based on the volume of stormwater, which is stored in the voids created by the chamber and the voids in the clear stone surrounding.

View Project

Alaska Highway Major Storm Sewer Relief

Fort St. John, BC Product: DuroMaxx® SRPE PipeThe City of Fort St. John's existing storm sewer infrastructure was unable to accommodate peak flow rates during periods of heavy rainfall. With a very tight construction window, DuroMaxx Steel Reinforced Polyethylene (SRPE) pipe was selected over concrete for its light weight, and ease of installation.

View Project

Bathurst Street Reconstruction

East Gwillimbury, ON Product: BRIDGE-PLATE®In order to manage growing travel demands, York Region commissioned the reconstruction and reconnection of Bathurst Street from Green Lane West to Holland Landing Road in the Township of King and Town of East Gwillimbury. During the design phase, several options were evaluated by the consultant SNC Lavalin. A Bridge-Plate solution was found to provide the best life-cycle cost while satisfying the project hydraulic, structural performance and design service life requirements. Two structures were required to span dry channel crossings for the passage of wildlife and a third middle crossing was required to span a stream channel. The Region incorporated three Bridge-Plate arch structures into their design to construct a road overpass over each of the three crossings in this area.

View Project

Big Slough Reline

Delta, BC Product: Multi PlateMulti Plate, a proven and versatile product since 1934, continues to provide cost-effective reline and stream crossing solutions. Armtec has a history of striving for excellence and is proud to continue the tradition with Strata-CAT.

View Project

Bridge Plate Reline Kamouraska, QC

Kamouraska, QC Product: BRIDGE-PLATE®In Monk Linear Park, near the town of Tourville in Kamouraska, a failing concrete bridge was in need of rehabilitation. The Ministry of Transportation of Quebec (MTQ) required an innovative solution to upgrade the deteriorating river crossing. Armtec proposed using Bridge Plate Deep Corrugated Steel Plate (DCSP) to reline the existing structure.

View Project

Buffalo Creek

Arras, BC Product: BRIDGE-PLATE®During the summer of 2011, a 3,000mm circular pipe was washed out six kilometers west of Highway 52 on the 206 Road at Buffalo Creek during the historic flooding that hit the British Columbia Peace Region. The British Columbia Ministry of Transportation was tasked with replacing a washed out drainage culvert and ensuring it would have sufficient hydraulic capacity for future floods. A new drainage structure was required to replace the washed out culvert. In order to deliver the project in a speedy and cost-effective manner, the government tendered the project as a Design-Build. DWB Consulting, with Armtec’s support, prepared a preliminary package for a steel pile supported 6,500mm span x 3,681mm rise Bridge Plate arch with Armtec’s Wire Mesh Wall system. Belvedere Contracting was the successful bidder on the project.

View Project

Carden Quarry Stockpile Tunnel

Brechin ON Product: Multi PlateThe Carden Aggregate Quarry is located north east of Brechin, Ontario. The Miller Group have operated this 332-hectare site since 1984. The quarry has a permanent processing plant in place and supplies a variety of aggregate materials for internal operations as well as municipal and private projects.

View Project

Chief William Commanda Bridge Rehabilitation

Ottawa, ON Product: Multi PlateThe Chief William Commanda Bridge was first built in 1870, with the superstructure reconstructed in 1926. The City of Ottawa purchased the railway bridge from the Canadian Pacific Railway (CPR) in 2005, and in 2019, the decision was made to construct a multi-use pathway (MUP) on the inactive bridge and rehabilitate the bridge’s substructure. This unused rail structure rehabilitation was part of the City of Ottawa’s active transportation strategy to provide alternative travel options across the Kichi Sipi Ottawa River between eastern Ontario and Western Quebec. It would connect pathways near Bayview Station in Ottawa and the southern tip of Gatineau Park, filling an approximate 4 km gap in river crossings between the Portage and Champlain bridges.

View Project

Compact Stormwater Treatment for Expanding Retail Space

Bradford, ON Product: Up-Flo® FilterThe Up-Flo Filter® is an advanced stormwater treatment solution for capturing very fine sediment, heavy metals, oil and nutrients from residential, commercial and industrial sites. The system is a multi-stage stormwater treatment system that combines pretreatment with fluidized bed filtration technology in a single device. The water flows in through an inlet grate and passes through filter modules that contain an engineered media mix designed to optimize pollutant removal by evenly spreading the flow across the entire surface area. A newer commercial development in Bradford, Ontario, SmartCentres was further expanding its’ retail footprint and turned to Armtec for stormwater drainage solutions.

View Project

CSP Sewer Reline for Busy Highway Intersections

Mississauga, ON Product: SteelCor Corrugated Steel PipeWith over 320,000 vehicles per day the intersection of Highways 401, 403 and 410 in Mississauga, ON is one of the busiest in North America. This location is also home to the confluence of several drainage paths, all of which are channeled into one major storm drain, which then pass beneath the intersection through a single storm sewer pipe. The owner, the Ministry of Transportation of Ontario (MTO) recognized that the storm sewer had to be rehabilitated.

View Project

Gannon’s Narrows Causeway Bridge Rehabilitation

Buckhorn and Pigeon Lakes, Ennismore, ON Product: Multi PlateThe Trent Severn Waterway is a national historic site that first opened in 1922. Connecting Georgian Bay and Lake Ontario, it is home to recreational boating and paddling enthusiasts alike. Midway along its length, boaters pass through the shallow waters of Gannon’s Narrows, connecting Buckhorn and Pigeon Lakes. The Gannon’s Narrows Bridge carries County Road 6 over the waterway providing easy access between the City of Peterborough and the northern Kawartha Lakes region.

View Project

Hiellen Sanitary Improvement Works

Masset, BC Product: DuroMaxx® SRPE PipeThe Old Massett Community is located in the north of Haida Gwaii, of the coast of British Columbia, near the Alaskan border. It is the unceded, ancestral and traditional territories of the Haida people. Old Masset Village Council required a solution to increase capacity and improve the operation of the Hiellen Longhouse Village sanitary system infrastructure. Hiellen Longhouse Village is an eco campground on the North Coast of Haida

View Project

Kinder Morgan Terminal, Edmonton AB

Edmonton AB Product: DuroMaxx® SRPE PipeThe Kinder Morgan Edmonton storage terminal, located in Sherwood Park, Alberta underwent a multi-phase expansion project between 2012 and 2014. The Edmonton Terminal Expansion Project (ETEP) included the addition of 15 merchant tanks bringing the total to 35 tanks with a combined storage capacity of 8 million barrels (1.27 million cubic metres). Upgrades to surrounding infrastructure included the installation of approximately 700 metres of Steel Reinforced Polyethylene (SRPE) pipe to re-direct a watercourse around a new retention pond into the North Saskatchewan River.

View Project

La Broquerie Bridge of Pioneers

La Broquerie, Manitoba Product: Bridge in a Box®This covered bridge crossing project was a WGI Westman Group cross division partnership involving Armtec, Behlen, Westman Steel, Meridian and Artspan. Russ Edwards, the owner and founder of WGI, grew up less than a mile away on his family farm in this rural municipality. This bridge project honours the Pioneers of the region by listing the names of families that settled here from 1875 to 1940.

View Project

Markham Storm Sewer

Markham, ON Product: SteelCor Corrugated Steel PipeThis project involved widening and improving the existing storm sewers on Warden Avenue in the Town of Markham. Some of the products supplied on this job included BOSS® 2000 HDPE storm sewer pipe, CSP culverts, and two stormwater treatment units.

View Project

Mine Truck Underpass Tunnels Cerro Verde Mine, Peru

Cerro Verde Mine, Peru Product: Multi Plate , BRIDGE-PLATE®Cerro Verde Mine is an open-pit copper and molybdenum complex near Arequipa in southern Peru. In operation since 1916, it is one of Peru’s oldest copper mines. With demands for copper growing worldwide, processing facilities were expanded as part of the Cerro Verde Production Unit Expansion project. Copper production was tripled to 600 metric tons of copper per year. Included in the infrastructure upgrades was the requirement for approximately 350 metres of conveyor and mine truck tunnels, varying in size from 3,990 to 7,695mm in diameter and buried up to 23 metres below course ore stockpile. New conveyor and mine truck underpass tunnels were required for the mine site as part of the Cerro Verde Mine facilities upgrade.

View Project

Multi Plate Reclaim Tunnel ORCA Quarry

Port McNeill BC Product: Multi PlatePolaris Minerals Corporation, based in Vancouver, British Columbia, is focused on supplying construction aggregates from Vancouver Island, BC, to coastal urban markets on the western seaboard of North America. The Orca Quarry, which is designed to produce 6 million tonnes of sand and gravel per year, is located on the east coast of northern Vancouver Island, 3.8km west of Port McNeill, British Columbia.

View Project

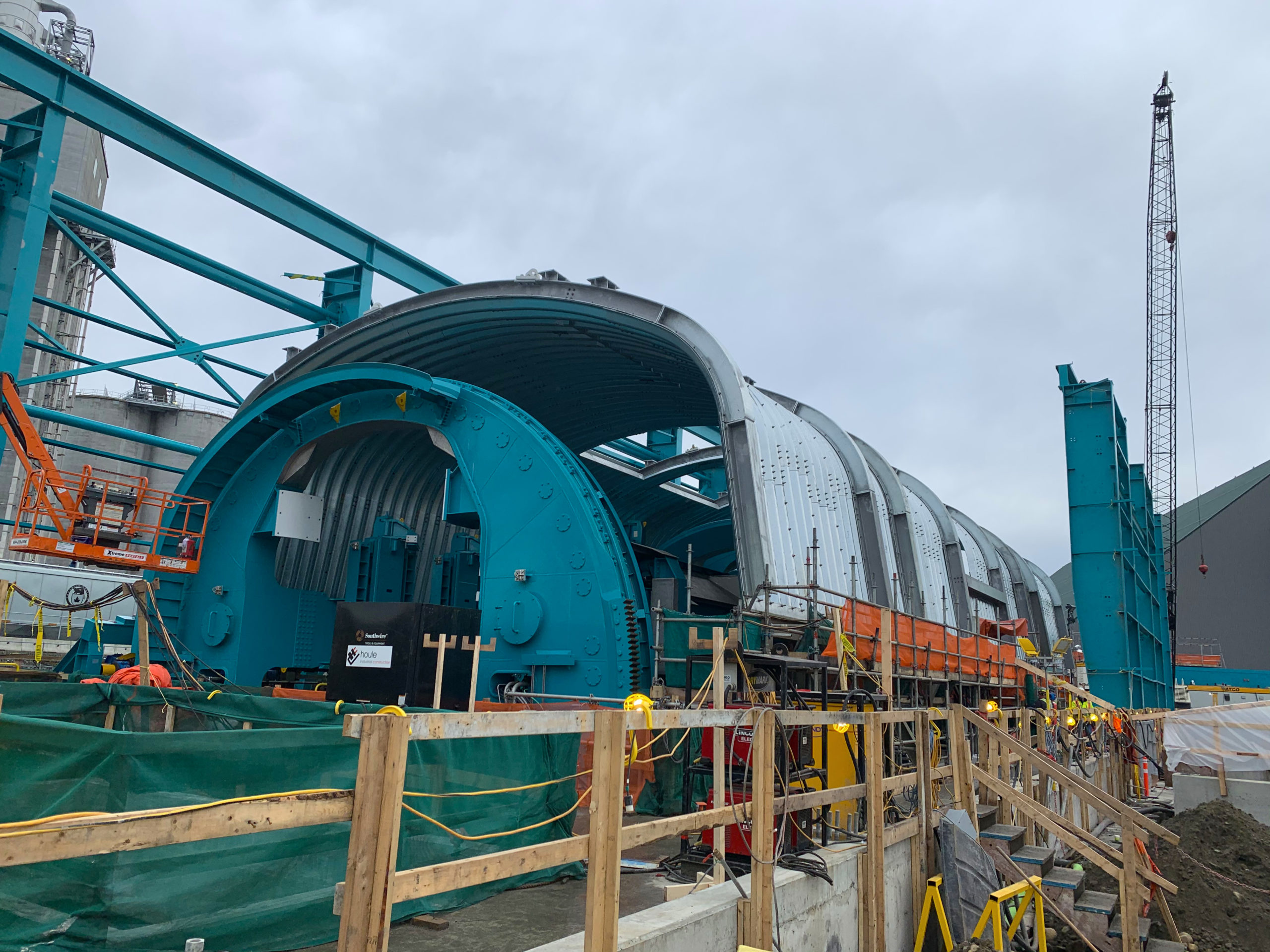

Neptune Bulk Terminals Dust Shroud

North Vancouver BC Product: BRIDGE-PLATE®Neptune Bulk Terminals, located in North Vancouver, transports Canadian commodities to markets all over the world. In their ongoing commitment to protecting the environment and minimizing the impact of operations, Neptune Bulk Terminals commissioned a new dust shroud for their Dumper Building. The structure would manage atmospheric emissions by preventing the spread of dust during operations. Neptune Bulk Terminals contacted Armtec through their consultants to determine whether a structural plate product could meet the project requirements. Armtec proposed Bridge Plate for its versatility, strength and ease of installation. They developed a custom solution designed to meet the needs of this unique project.

View Project

Parkdale Creek BC Stream Crossing

Parkdale Connector Lanford, BC Product: BRIDGE-PLATE®The Westhills lands encompass 209 hectares of rolling sloped lands, knolls, and rocky outcroppings, and are located in the City of Langford, British Columbia. At Westhills, sustainability equates to environmental stewardship—it is the result of a careful assessment of every decision and action they take that relates to the land, water and air. A 12mm span x 5.9mm rise Bridge Plate arch structure was selected for this water crossing. It delivered both cost savings and fit into the developer's vision of environmental stewardship.

View Project

Pinkerton Tunnel Rehabilitation

Southwestern Pennsylvania, USA Product: BRIDGE-PLATE®The Great Allegheny Passage (GAP) is one of the most picturesque converted rail-trails east of the Mississippi River. Connecting Washington D.C. to Pittsburgh, Pennsylvania this multi-use trail is enjoyed daily by bikers and hikers as it twists its way through the Appalachian Mountains. Near the town of Somerset, the busy trail took an abrupt turn to detour around the historic Pinkerton Rail Tunnel. The tunnel, originally built in 1911 to connect the former Western Maryland Rail-line to the bustling Pittsburgh region, was closed since the GAP trail opened in 1999. Much of the tunnel interior had cracked and spalled concrete walls and in some areas the roof had collapsed leaving large holes in the ceiling. In the fall of 2014, engineering consultants Gannett Fleming contacted Armtec for assistance to rehabilitate the 270m long concrete tunnel and eliminate the 2.5km detour around the failing structure.

View Project

Richmond Industrial Center Stormwater Detention

Richmond, BC Product: HydroStor® Stormwater ChambersThe Richmond Industrial Center development is located on an old landfill site along the shores of the Fraser River. It includes twelve buildings, occupying 170 acres plus 40 acres of green space and will generate 4,800 new jobs for the area. Typically, no increase in water level would be allowed within the City’s drainage system compared to the pre-development condition. A stormwater management plan was therefore required as part of this new development.

View Project

Shamrock Lake Tunnel Liner Plate

Shamrock Lake ON Product: Tunnel Liner PlateA concrete box culvert located beneath Highway 11 near Shamrock Lake, about 31.5 km North of Nipigon was in critical condition. Constructed in 1938, the existing box culvert was quickly eroding and crumbling. Concrete patching and crack repair alone would not restore the integrity of the culvert and it was only a matter of time before the highway would require closing for repair. Located under 16.3m of cover and servicing a critical spawning habitat for Brook Trout, a trenchless solution was preferred over full replacement. Armtec proposed rehabilitation of the existing structure using Tunnel Liner Plate.

View Project

Smoky River Bridge-In-a-Box

Falher, AB Product: Bridge in a Box®A section of road regularly impacted by spring flooding in the Municipal District of Smoky River, Alberta required a road grade elevation and new bridge crossing. Several options were investigated and Armtec’s Bridge-In-a-Box proved to be the most cost-effective option for this low volume road.

View Project

Springdale UltraFlo Storm Sewer

Springdale, NL Product: UltraFlo Corrugated Steel PipeIn late November, as the construction season was winding down, a large tender was called for the small municipality of Springdale in Central Newfoundland. The town's storm sewer system required the addition of 590m of 1,050m diameter pipe. The original specification called for High Density Polyethylene (HDPE) pipe. With limited supplies and a tight construction window, an alternative product was required.

View Project

Sproat Lake CSP Reline

Sproat Lake, B.C. Product: SteelCor Corrugated Steel PipeA Multi Plate structure, located along the main highway between Port Alberni and Tofino, BC, was nearing the end of its service life and in need of replacement or rehabilitation. Replacing the structure required a full road closure, which was not feasible given its close proximity to a natural pond and fish habitat. A rehabilitation solution was selected as the only viable option in terms of the deadline for project completion and cost-effectiveness targets.

View Project

SRPE Pipe Rehabilitation

Atikokan ON Product: DuroMaxx® SRPE PipeA forty year old asphalt dipped galvanized Corrugated Steel Pipe (CSP) culvert near Atikokan, Ontario was identified for maintenance by the Ministry of Transportation Ontario (MTO). Once inspection began, it was discovered the culvert had collapsed and was in need of replacement. A new large diameter pipe was required, capable of delivering a 75 year Design Service Life (DSL) under challenging environmental conditions.

View Project

St. John’s International Airport Bin Wall

St. John's, NL Product: Bin WallSt. John’s International Airport services approximately 1.5 million passengers per year connecting Newfoundland and Labrador to the rest of the world. Forecasts indicate that approximately 20 million passengers will travel through the airport by 2020. To accommodate this increase the airport has implemented a 10 year Improvement and Expansion Plan. Included in the plan was the construction of a bin-type retaining wall system to support a new parking area.

View Project

St. Kitts Rockfall Protection Tunnel

St. Kitts and Nevis Product: BRIDGE-PLATE®The South-East Peninsula Road is the main highway on the island of St. Kitts joining the capital city of Basseterre to the beaches of the south and the ferry dock to neighbouring Nevis. Sections of the road were built through the steep hills on the Peninsula. Along the Timothy Hill Road cut, just outside Basseterre, the hills were highly unstable and losing their rock faces to the salt and weathering of the Caribbean winds. Mudslides, large boulders and rock-fall threatened the safety of motorists and pedestrians travelling this route.

View Project

Terra Nova Tunnel Liner Plate Extension

Terra Nova National Park NL Product: Tunnel Liner PlateIn May 2014, Armtec Tunnel Liner Plate was used to rehabilitate a 47 year old Multi Plate structure in Terra Nova National Park in Eastern Newfoundland. Two years later, the road above the culvert required widening to create a new passing lane and improve traffic flow. The existing Tunnel Liner Plate was extended to accommodate the wider road.

View Project

Vaughan Stormwater Management

Vaughan, ON Product: HydroStor® Stormwater ChambersExpansion of the Vaughan City Hall western parking lot required additional stormwater storage. With land values at a premium, the city looked towards an underground storage solution. Armtec was contacted to present an alternative chamber product than that originally specified in the design. HydroStor was presented as the most cost-effective option able to meet the site performance requirements.

View Project

West Creek, BC Multi Plate Crossing

Langley, BC Product: Multi PlateA failed culvert in the Township of Langley, BC was in need of urgent repair. An intense three-day rainfall event caused significant erosion at the inlet, allowing surcharged water to ‘pipe’ along the culvert eroding the outlet bank of West Creek on the western side of 252A Crescent.

View Project

Trusted By: