Multi Plate Reclaim Tunnel ORCA Quarry

Product Utilized:

Multi Plate

Product Utilized:

Multi Plate

The Challenge

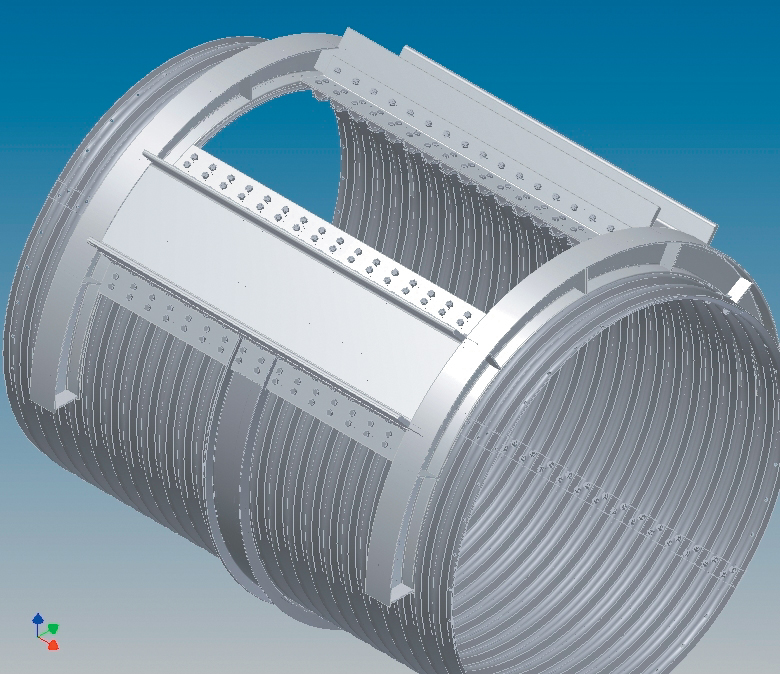

In order to load the quarry’s sand and gravel production onto freighters via a conveyor system, the aggregate required stockpiling above a reclaim tunnel—this is where the Armtec story begins. In the design stages of the project a year prior to construction, Armtec provided design and budget information to AMEC for the specified 3.67m diameter Multi Plate Round Structure under two sand and gravel piles, each having a height of 31m.

The Solution

To support this significant dead load, the resulting 264m long Multi Plate Round Structure was designed in the heaviest wall thickness possible (7mm) with a custom punched bolt pattern (2 bolts per corrugation). To permit emergency egress from the tunnel, Armtec designed and supplied a 1.0m diameter Hel-Cor CSP escape tunnel mid-way along the Multi Plate Structure. Prior to construction, Armtec Engineers conducted a pre-construction meeting to review plate assembly and backfill specifications and walked the site. Within four weeks, plate assembly was completed by the six-person crew using a telescoping crane. The owners completed the backfill installation of the structure with preapproved on-site granular materials. From pre-design work to manufacturing and start-up assistance with numerous site visits by its Engineers, Armtec provided a complete cost-effective solution for this mining application.

“The Armtec team proved responsive and dealt promptly and effectively with engineering design issues as the project evolved. Delivery of the Multi-Plate tunnel components was timely and in accordance with our agreed schedule. I was very pleased with all aspects of the relationship with Armtec.”

Herb Wilson, Vice President, Polaris Minerals